tennessee eastman process

This chapter presents a comprehensive analysis and modelling of the Tennessee Eastman challenge problem. The proposed scheme is tested by the Tennessee Eastman platform.

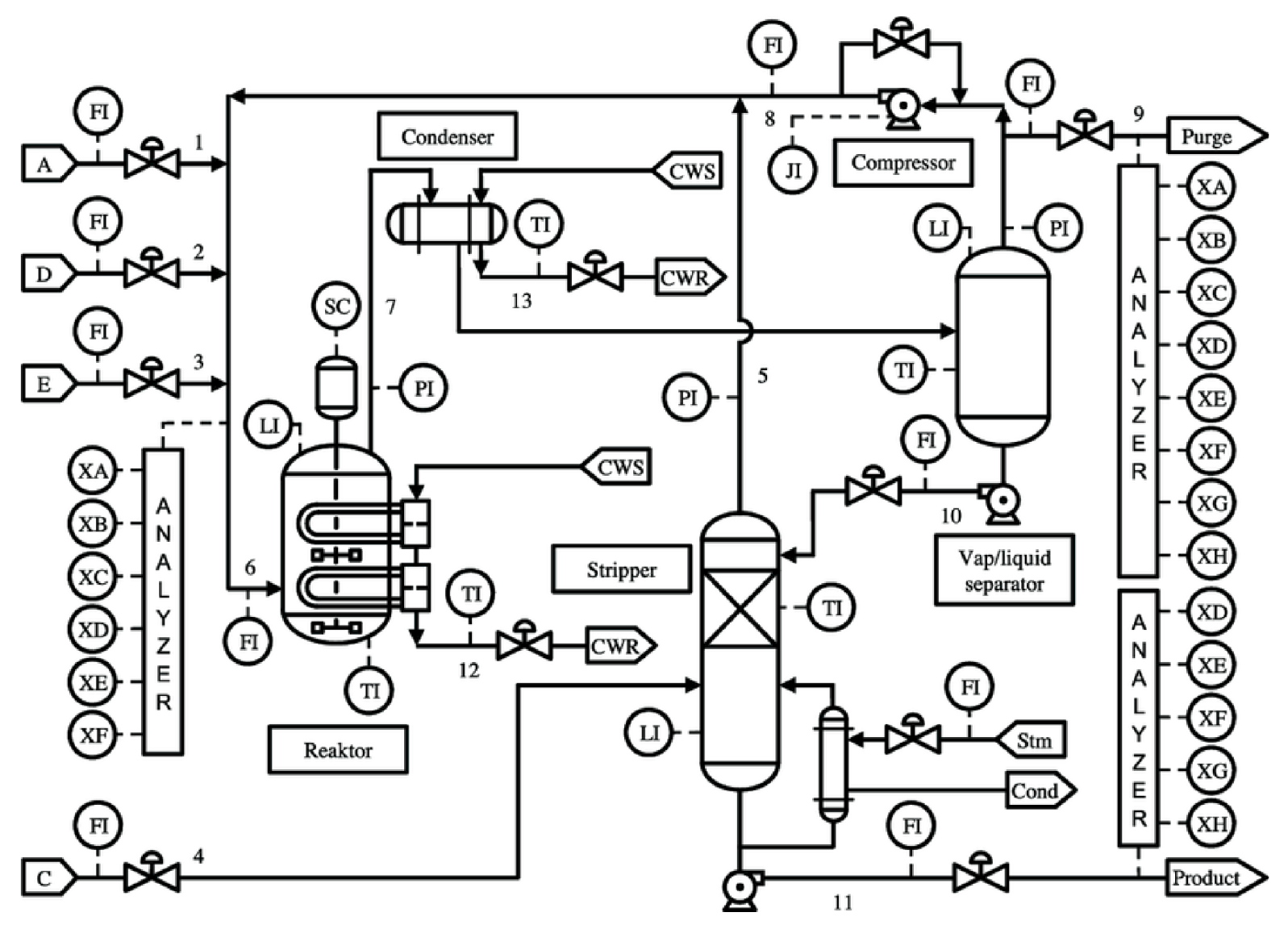

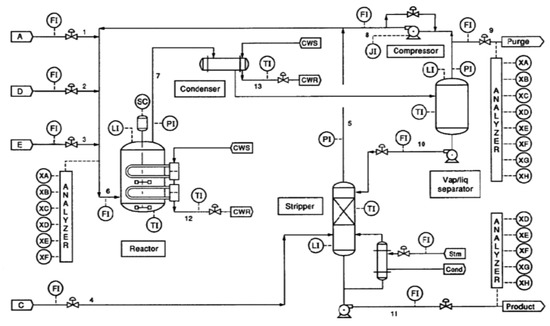

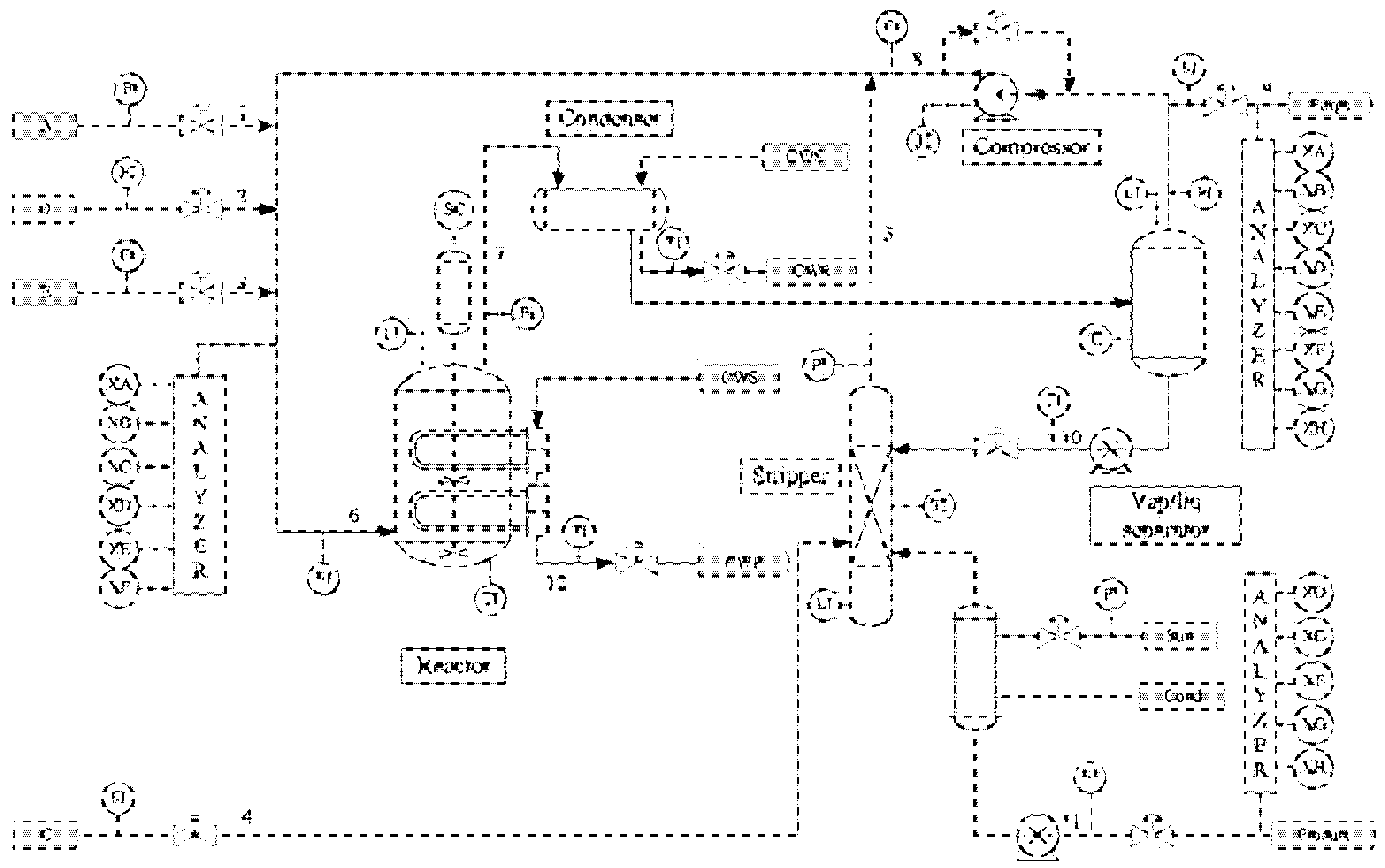

Flow Chart Of The Tennessee Eastman Process Download Scientific Diagram

Tennessee Eastman initially manufactured methanol methyl acetone and various by-products through the dry distillation of wood but Eastman soon realized the Kingsport site.

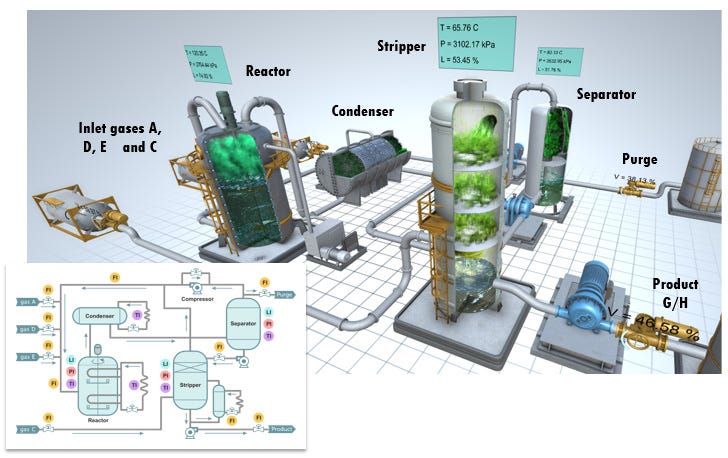

. The Tennessee Eastman Process is a large scale process largely used for benchmarking. A two-phase reactor where an exothermic reaction occurs a separator a. The Tennessee Eastman Process TEP model consists of four main units.

The TE process simulator emulates a continuous chemical process originally developed for studies and development of engineering. The Tennessee Eastman process simulator. The TEP variables columns 4 to 55 were sampled every 3 minutes for a total duration of 25 hours and 48 hours respectively.

What makes it especially important is that the data recovered from this. The application to Tennessee Eastman process has proved the sensitivity of the method which is helpful to taking measures on time and stablizing the product quality. Tennessee Eastman acetic anhydride process Acetic anhydride is produced by carbonylation of methyl acetate in a process that is similar to the Monsanto acetic acid synthesis.

The TE problem was. Both a simplified model of the system as well as a full process model that. Fault diagnosis is important to the industrial process.

Its results show that this scheme has a good performance in reducing the faulty false alarms and missed detection. Chemical process is proposed by JJ. The products leave the reactor as vapors and are fed into the.

A combined monitoring scheme with fuzzy logic filter for plant-wide Tennessee Eastman Process fault detection. Fulltext Access 31 Pages 2018. The files give operating conditions at 6 different steady state operating conditions described in the paper Optimal Steady state Operation of the Tennessee Eastman Challenge Process N.

Note that the faults were introduced 1 and 8. Selection of non-zero loadings in sparse. The Tennessee Eastman process is a typical industrial process that consists of five main process units.

依据实际化工反应过程美国 Eastman 化学公司开发了具有开放性和挑战性的化工模型仿真平台-Tennessee Eastman TE仿真平台其产生的数据具有时变强耦合和非线性特. When you look through papers on anomaly detection in the field of process engineering one name above all others keeps on cropping up. The Tennessee Eastman Process TEP.

Gases interact exothermically inside the reactor. Since its introduction in the 1990s typical. Production ready statistical process monitoring and anomaly detection program for a typical chemical production plant.

The Tennessee Eastman TE process is a chemical testing experimental platform that developed from a realistic chemical joint reaction process. However the original version of the model is very nonliear and difficult to use to. This paper proposes an orthogonal incremental extreme learning machine based on driving amount DAOI-ELM for recognizing.

The TE process is a. This commit does not belong to any branch on this repository and may belong to a fork outside of. DESCRIPTION OF THE SIMPLIFIED TE MODEL The Simplified Tennessee Eastman TES model Ricker 1993 is a simplification of the model described in Downs and Vogel.

The TEP is essentially a real industrial process that was modeled computationally in 1993 by Downs and Vogel. Vogel which is the process control case based on the Eastman practical industrial process as shown in Figure 3. In this paper a closer look at the underlying computer code of the well-known Tennessee Eastman Process model is taken.

Tennessee Eastman Process Simulation Data for Anomaly Detection Evaluation Introduction Modern Industrial Control Systems ICS deals with multivariate time series data.

Process Flow Diagram Of Tennessee Eastman Process Download Scientific Diagram

The Tennessee Eastman Process An Open Source Benchmark Keepfloyding

Flow Sheet Of The Tennessee Eastman Process Tep Indicating The Download Scientific Diagram

Sensors Free Full Text Fault Detection And Diagnosis Using Combined Autoencoder And Long Short Term Memory Network Html

An Improved Approach For Fault Detection By Simultaneous Overcoming Of High Dimensionality Autocorrelation And Time Variability Plos One

The Flowchart Of The Tennessee Eastman Process Download Scientific Diagram

A Diagram Of The Tennessee Eastman Process Download Scientific Diagram

Diagram Of The Tennessee Eastman Process Tep Simulation 45 Download Scientific Diagram

Pdf Revision Of The Tennessee Eastman Process Model Semantic Scholar

Case Study 1 Tennessee Eastman Process Tep Downs And Vogel 1993 Download Scientific Diagram

Tennessee Eastman Process Simulation Data For Anomaly Detection Evaluation By Mrunal Sawant Medium

A Diagram Of The Tennessee Eastman Process Simulator 13 Download Scientific Diagram

Adversarial Autoencoder Based Nonlinear Process Monitoring Sciencedirect

Processes Free Full Text Real Time Industrial Process Fault Diagnosis Based On Time Delayed Mutual Information Analysis Html

Processes Free Full Text A Novel Mutual Information And Partial Least Squares Approach For Quality Related And Quality Unrelated Fault Detection Html

Process Flowsheet For The Tennessee Eastman Process Download Scientific Diagram

Comments

Post a Comment